Custom Injection Mold Making Services

Great Price - Massive Engineering Support

- Injection mold making (production, stack, two shot, and more)

- Injection molding a la carte engineering

- Moldex3D a la carte MFA analysis

- Injection mold project management services at your existing supplier

- Quality control services at your existing injection mold supplier.

Injection Molding Services

Injection Mold Building Services

To have an injection mold built offshore and run well back in your home factory takes a lot of really good communication and cultural manufacturing understanding. A lack this can lead to spending extra time and money fixing injection mold mistakes downstream. But many projects need offshore pricing to make it in the market, so what to do? At Jade Molds, our approach to offshore injection mold making eliminates issues via a USA approach to engineering, mold making, project management, and quality control. Plus communication is always with a native English speaker. Learn more…

Injection Molded Production Part Services

With 28 in-house injection mold presses ranging from 50 T to 1100 T not only can we run multiple mold trials, we are positioned well to run support part production for your project. If we have built you an injection mold for export to your country and you need bridge part production we can certainly support your short term part production needs. Or maybe you would like us to build the mold, store it, and run production parts for you when needed. Either way, think Jade Molds for steady part production or bridge part production support . Click above to Learn more..

Automotive Molding Services

Some North American and European customers come to us for automotive rapid tooling needs, some for Automotive production molds, and some for both. Our USA with engineering team use first-in-class Moldex3D software to assist them in analyzing your mold part design and our mold design. When Moldex3D software is leveraged correctly it is like doing first shots right on the screen, a tremendous time saver and advantage for our automotive customers. Learn more…

Rapid Tooling Services

Rapid tooling (rapid injection molding) programs in Europe and North America traditionally use aluminum to fabricate their rapid tools. Why? While suppliers will talk about several advantages to using aluminum the real reason comes down one primary factor, price. Making rapid tools from aluminum enables Western mold makers to compete on price with China mold makers. Yes, timing is fast with aluminum but it can also be fast with P20. Jade’s P20 rapid tool programs deliver massive ROI. Learn more…

Pet Treat Injection Molds

Do you have an unusual injection molding application? How about injection molds for pet treats? High cavitation molds. Molds that can run fast and smooth in your presses. Hot runners not a problem. Our mold building in China (managed by Westerners) can include features like these and others to meet your highly specific injection molding needs. Specialty resins? Not a problem. Specific injection mold steel? Not a problem. Learn more…

General Purpose Molds

The single biggest factor that prevents injection molders from winning more production jobs is part price and the single biggest factor in determining part price is the cost of the injection mold tool. We will not only deliver you a great injection mold tooling price but also the Western quality (Western engineered mold design, project managers, mold makers, quality control, engineering ) you need for truly great offshore injection molds. Always communicate in native English with our team. Learn more…How can we help you?

- Looking for an injection mold making quote?

- Need a project review of an existing design you have?

- Have questions about how mold making in China works?

- Looking for A La Carte engineering or Moldex3D services?

Moldex3D Engineering Services

Moldex3D is not your average mold flow analysis. This powerful software is top in the industry and when you leverage this software properly it is like doing first shot on the screen. We include Moldex3D with all of our projects for a couple of key reasons. i) Identify design issues and fix issues faster before cutting steel ii) Jade saves time (money) on mold trials as Moldex3D helps us deliver a mold to you after the first 1 or 2 test shots and we pass these savings on to you iii) Moldex3D helps to determine your optimal Injection Molding Process for your press. Learn more...

CNC Machining Services

From prototype to production (low and high volumes), we offer precision CNC machining services to customers from all over the world. As product developers with over 20 patents in-house we understand how vital rapid manufacturing is for speed to market success. Appearance models with perfect surface finishing. Fully functional prototypes that are tough as nails. Multiple iterations of the same designs with slight variations.

The only questions is, how can we help you? Learn more…

Engineering Services

Our engineering teams are trained in multiple CAD programs as well as Moldex3D. A la carte engineering services are available for those customers who are not building an injection mold with us. Services that can help to qualify your part design accurately, fast, and at a price point that works. Learn more…

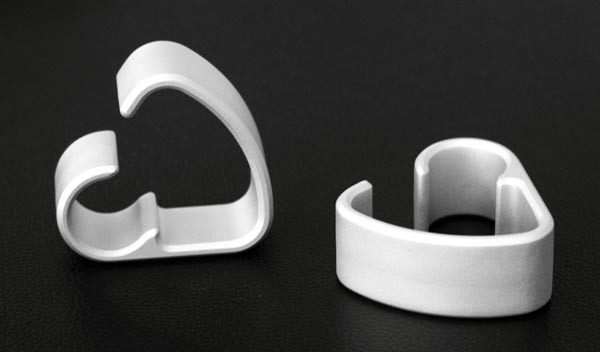

Mold Base Services

Why are your skilled mold builders spending time fabricating mold bases? Keep your skilled team focused on skilled injection mold building tasks. Try our complete custom injection mold base solutions that will help to keep your business globally competitive. Learn more…