Bad molds can impact brand perception, delay time to market, decrease revenue and destroy trust with shareholders and retailers. That’s why we prioritize quality and durability at every stage, backed by our global manufacturing support across the USA, China, Vietnam, and India.

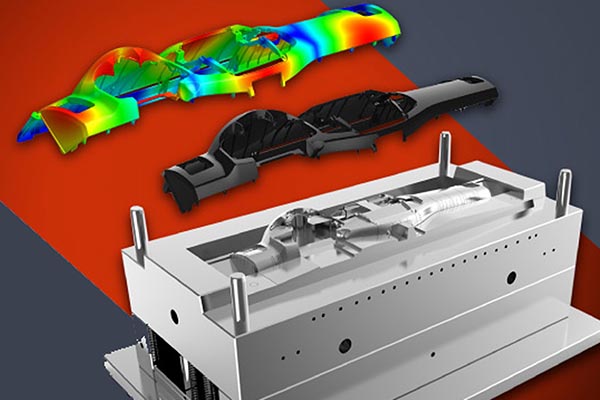

View Sample Full Moldex3D Report: This is a massively detailed report. Our engineers setup the parameters (no easy task) so that the report Moldex3D generated is a highly accurate future prediction of your mold flow.

For many part designs, this full report from Moldex3D is not required and can be a bit confusing. So our team creates a Moldex3D Level 3 summary report on the KEY issues.

View Sample Moldex3D Level 3 Summary: Moldex3D is a great mold flow analysis tool that assists our engineering team in identifying future hard to know issues.

A great summary of the FULL Moldex3D report that includes: fill, pack, cooling, and warpage mold flow analysis. The most relevant data in summary form that is easy to review, understand, and action on.

View Sample Moldex3D Level 2 Summary. This summary includes details for Moldex3D similar to a Moldex3D Level 3 mold flow analysis without packing, cooling, and warpage.

With a focus on American values and a global presence across the USA, China, Vietnam, and India, we ensure seamless, transparent project management, so you never face unexpected delays or costs.

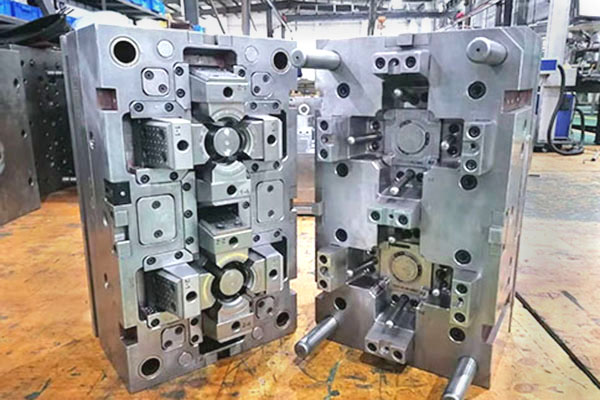

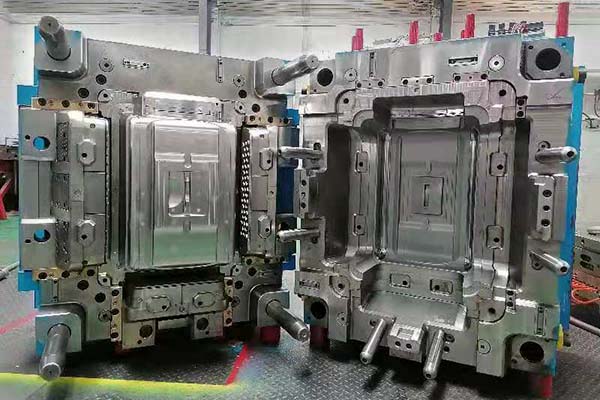

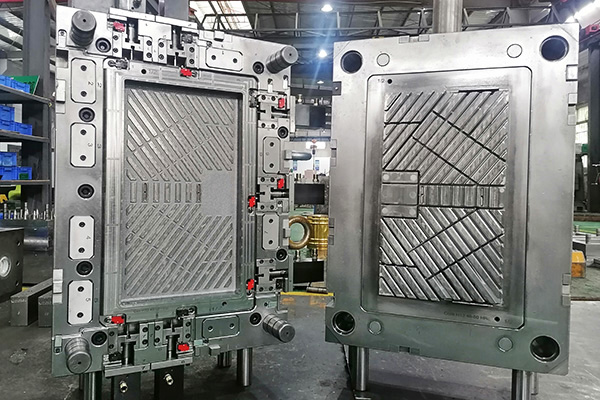

Precision Craftsmanship Meets Integrity—Jade Molds is Your Trusted Partner in Injection Mold Making Excellence

Our U.S. project managers ensure every step is clear, reliable, and tailored to your needs, from initial quote to final delivery.

View Sample Moldex3D Level 3 Summary: Moldex3D is a great mold flow analysis tool that assists our engineering team in identifying future hard to know issues very early on, so we can fix early and mitigate potential future risk.

A FULL Moldex3D analysis report is a massive amount of data so our team reviews that data and places the most relevant data into a summary document that is easy to review, understand, and action on.

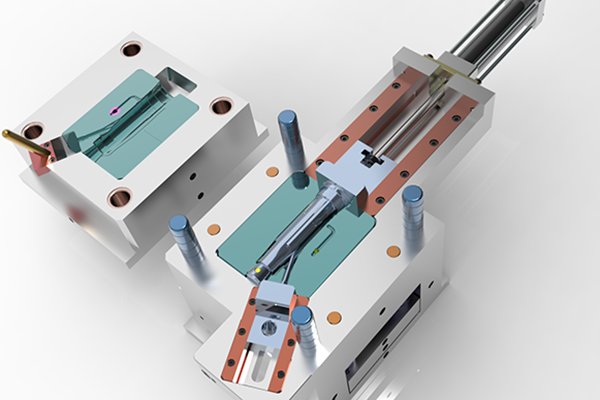

View Sample DFM: We start off your injection mold project with a thorough review of your part design and come back to you with any potential issues are hard issues that we find.

As long as there are no major issues we start your mold design right away and work on both the DFM and Mold Design with you concurrently.

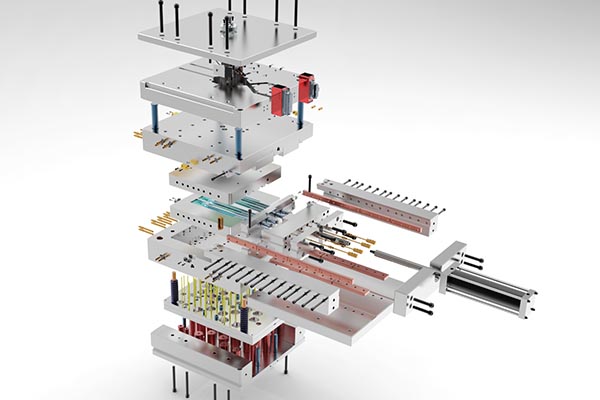

View Sample Gantt Chart: Our custom blueprint driven PM system let’s us know (at a glance) the exact status of any project or task, including what’s due, on-time, or late. Auto email alerts and daily PM reviews keep your projects on track.

Tasks can start earlier or later than what is shown here. When this happens dependencies shift other tasks accordingly.

Say goodbye to late-night calls, communication breakdowns, and hidden fees with our American-led team that puts your business first.

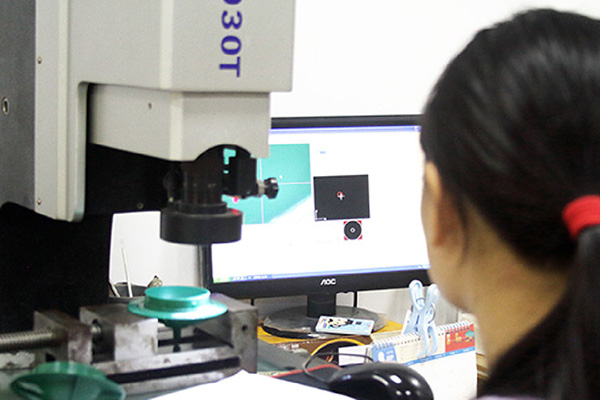

View Sample Report: we check incoming hardness against the approved DFM and send to you.

View Sample Report: this is a simple double check to ensure steel hardness before your mold ships

View Sample Report: we only create this report when needed. Very often after T1, but might not be needed after T2.

View Sample Report: a Final QC check to make sure the mold is fit for shipping.

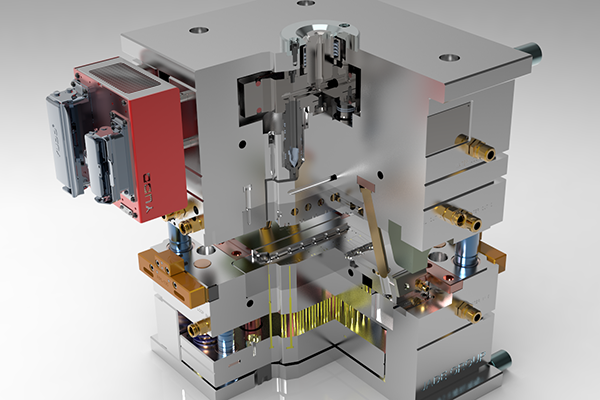

View Sample Report: if your mold is a hot runner we perform a design check at engineering phase and a physical check once hot runner arrives. There are also several other hot runner QC checks in our other QC forms.

View Sample Report: we completely tear down your mold to identify any and all issues. If issues we still send you the report and work on fixing any issue quickly in preparation for you approving mold shipment.

View Sample Report: Done on shipping day as a final double check to make sure the mold is packed correctly and to ensure any extra components or spare parts you ordered also get shipped.

View Sample Report: We update you when your mold is picked up and follow up with further updates when tracking available.

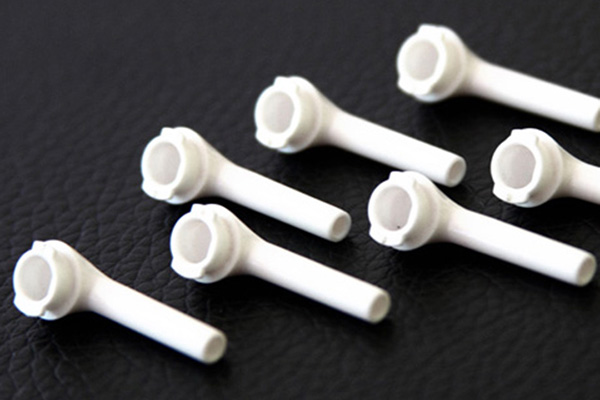

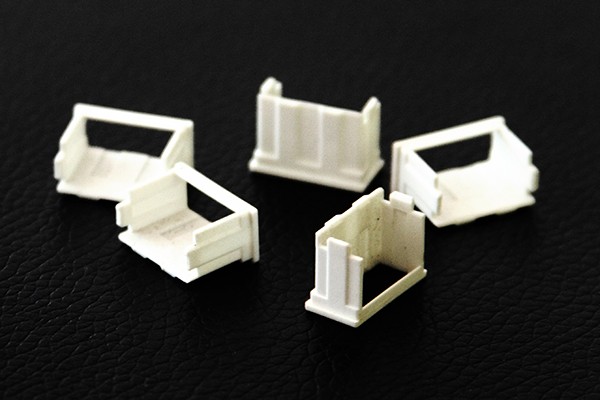

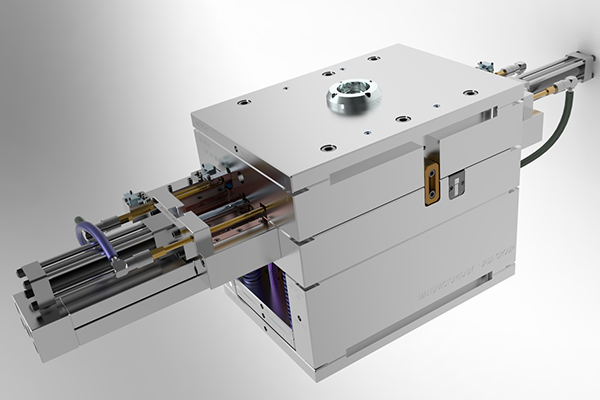

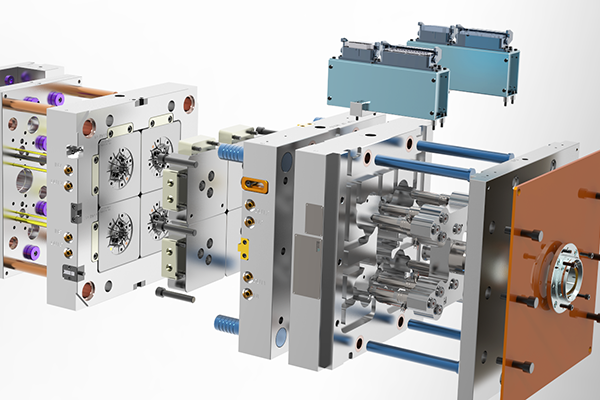

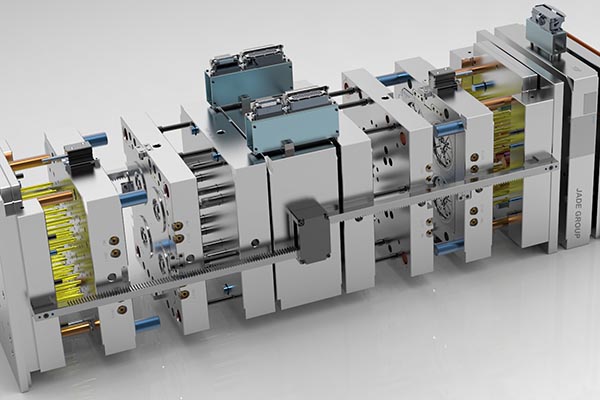

Why are your skilled mold makers machining mold bases? Jade Molds custom mold base solutions are built to keep you competitive and to keep your skilled team on skilled tasks for greater efficiency and productivity.

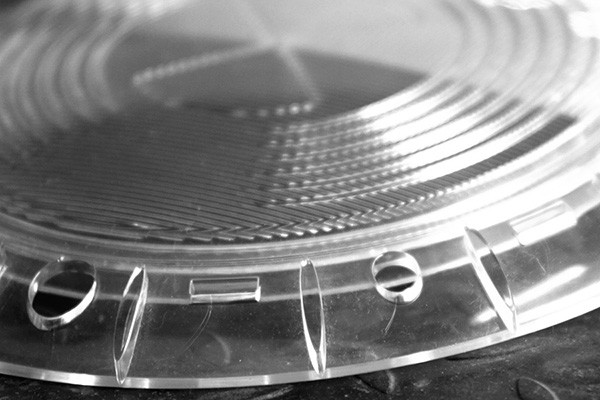

We include and Moldex3D on all injection mold projects. With this engineering assist, our team can dive deep on a manual DFM analysis for your project. A-la-carte engineering services also available.

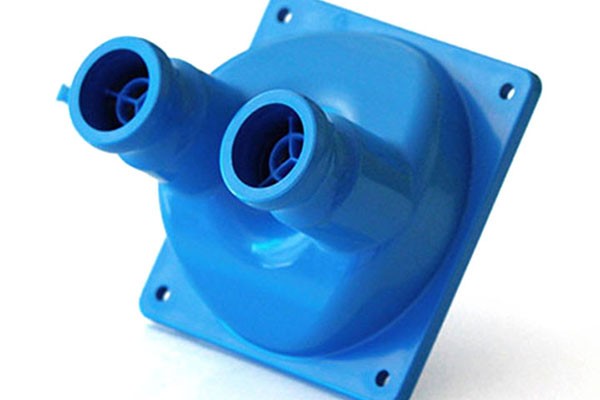

Our P20 rapid tools deliver significantly more parts with a faster turnaround for higher ROI when compared to USA rapid tooling programs. Complicated parts? Not a problem.

Not sure where to start? Our experts will diagnose your current mold challenges for free and offer solutions to fit your exact needs. With Jade Molds, you don’t have to pay more for great customer service or project transparency. Our commitment to quality is baked into every project.