Say goodbye to late-night calls, communication breakdowns, and hidden fees with our American-led team that puts your business first.

View Sample Report: we check incoming hardness against the approved DFM and send to you.

View Sample Report: this is a simple double check to ensure steel hardness before your mold ships

View Sample Report: we only create this report when needed. Very often after T1, but might not be needed after T2.

View Sample Report: a Final QC check to make sure the mold is fit for shipping.

View Sample Report: if your mold is a hot runner we perform a design check at engineering phase and a physical check once hot runner arrives. There are also several other hot runner QC checks in our other QC forms.

View Sample Report: we completely tear down your mold to identify any and all issues. If issues we still send you the report and work on fixing any issue quickly in preparation for you approving mold shipment.

View Sample Report: Done on shipping day as a final double check to make sure the mold is packed correctly and to ensure any extra components or spare parts you ordered also get shipped.

View Sample Report: We update you when your mold is picked up and follow up with further updates when tracking available.

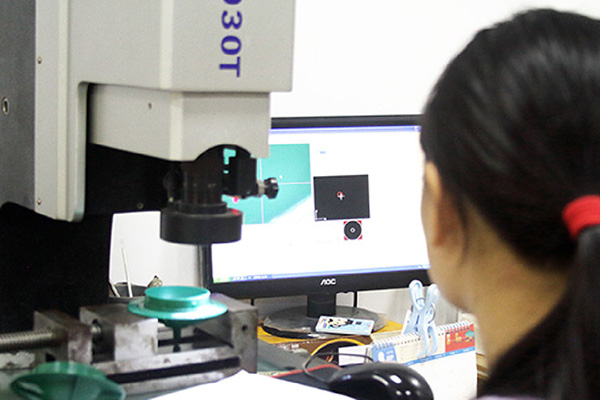

Need help with quality control at your supplier Offshore? Jade Molds is here to represent your interests, whether it’s overseeing a mold trial, troubleshooting a problematic mold build, or rescuing and repairing a mold at our facility.

Our team of experienced Westerners on the ground Offshore ensures seamless communication in native English, providing faster problem-solving and more options for your project.

We specialize in American-quality injection mold building and production, with additional expertise in rapid prototyping and product development. Our team also frequently provides quality control for part production and product assembly beyond our core services. Traveling overseas to inspect a product run can be costly, while skipping it altogether risks significant quality issues later. Jade’s QC services offer the perfect balance of cost-effectiveness and reliability. With veteran US-based manufacturers on the ground, we ensure your project meets the highest standards.

All rights reserved by:

JADE Group International LLC (JADE Molds)