We understand how critical your injection molding schedule is to your vehicle launch timelines—and we’re here to help you stay on track.

At our ISO and IATF-certified factories Offshore, we combine Western mold-making methodologies with on-the-ground management by experienced Western professionals. This ensures your mold meets specifications, performs well in trials, ships on time, and runs smoothly in your press.

At Jade Molds, we serve North American and European customers with rapid tooling, production molds, or a combination of both. Every mold project starts in the USA with our injection mold engineering team conducting detailed Moldex3D analyses as a standard practice. Using Moldex3D effectively allows us to simulate first shots digitally, saving both time and money for our automotive injection mold customers.

In about 80% of the projects we handle, we identify design improvements that enhance production outcomes. Moldex3D also helps us optimize process settings, ensuring production goals are achievable before any steel is cut—a significant advantage for our customers.

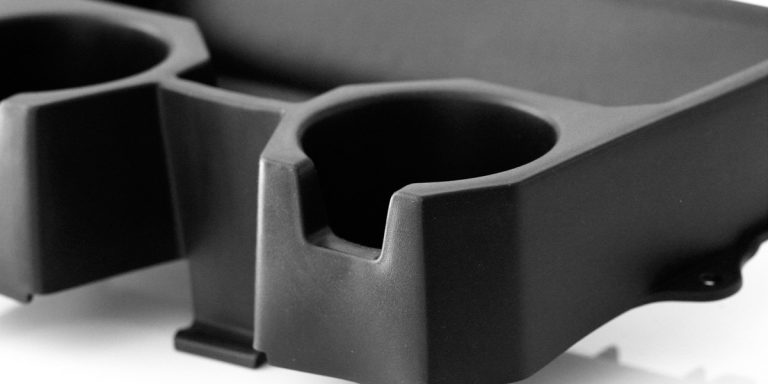

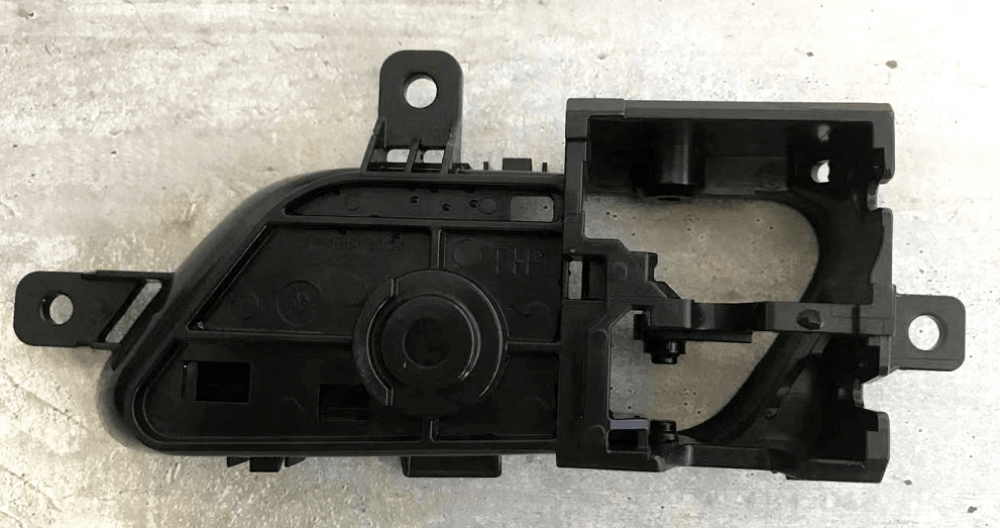

Our interior automotive mold capabilities include components such as dashboards, glove compartments, air ducts, center consoles, door handles, window controls, pillars, and steering column elements.

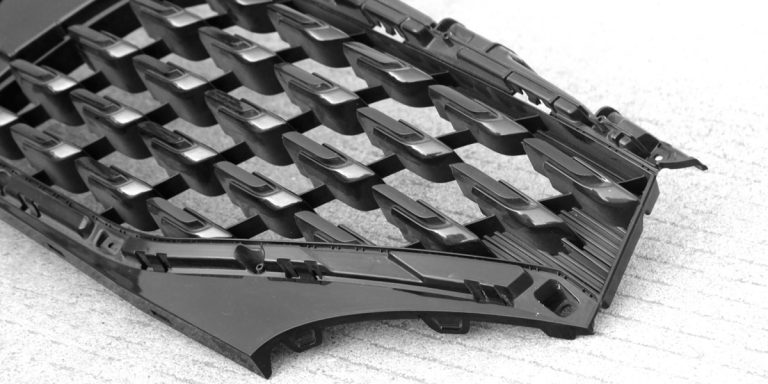

For exterior automotive molds, we specialize in grilles, bumpers, trunk trim, door panels, fenders, wheel arches, floor rails, and more.

With Jade Molds, you gain expertise and technology that streamline your projects and deliver high-quality results.

Choosing the Right Automotive Mold-Building Partner Offshore

Finding a reliable automotive mold-building partner Offshore can be challenging. Many of our customers have experienced issues with other suppliers, including poor communication, inconsistent quality control (QC), hot runner malfunctions, material problems, mold trial failures, and molds that don’t function as intended once delivered. Here’s how Jade Molds addresses and solves these common challenges:

Effective communication is essential. Jade Molds bridges language and cultural differences with a dual presence in the USA and Offshore.

Quality control is often inconsistent with many Offshore suppliers, sometimes relying on a single individual. If that person leaves, quality can decline drastically.

Hot runners require meticulous QC and expertise to prevent costly issues.

From start to finish, we provide expert guidance, robust QC systems, and clear communication, ensuring your mold performs flawlessly in your production environment. Partner with Jade Molds to eliminate common mold-building headaches and achieve success with your automotive projects.

1. Fake Material Problems

In automotive mold trials, receiving test parts made from 100% certified material is non-negotiable. Tight schedules leave no room for delays caused by substandard or fake materials.

2. Mold Trial Issues

Many Offshore mold makers cut corners during trials, treating them as a formality to get the mold approved and shipped. This approach often leads to problems later.

3. Molds Not Running Properly in Your Press

The worst-case scenario: a mold that doesn’t perform in your injection press, causing downtime, lost production, and expensive fixes in your home country.

All rights reserved by:

JADE Group International LLC (JADE Molds)