Jade Molds offers competitive injection mold pricing that keeps you globally competitive while providing unique savings of up to 50% on injection mold tariffs. Our comprehensive engineering support ensures your project is highly qualified, enhanced by advanced DFM and Moldex3D analysis included in every mold project. With a USA-based approach to offshore mold making and project management, we prioritize efficiency and transparency. Our custom QC app streamlines live data capture for faster issue resolution, while crystal-clear communication is guaranteed through native English-speaking project managers. You save on mold pricing, engineering support, DDP shipping and tariffs, and travel, with all paperwork handled through Jade Molds’ USA-based company—no need for international wire transfers.

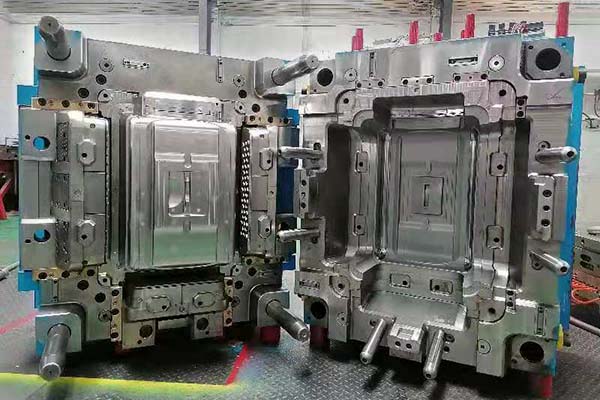

The biggest challenge for injection mold makers in winning more part production jobs is reducing part price—and the cost of the injection mold tool is the primary driver of that price. At Jade Molds, we not only provide highly competitive injection mold tooling prices but also deliver a USA-level approach to offshore mold making. Our process includes enhanced DFM, precise mold design, professional project management, meticulous quality control, and seamless communication.

With native English speakers managing communication, we ensure a smooth offshore experience and quick, efficient handling of ECN requests. The result? Injection molds that perform flawlessly in your presses, meeting your exact production requirements.

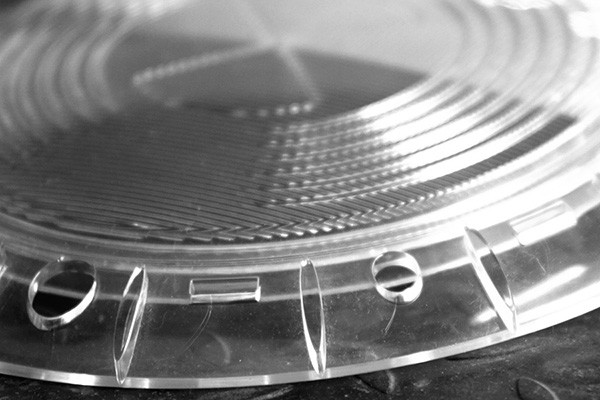

If you need high-volume production parts, our injection mold tooling is the ideal solution. We offer a range of hardened steels and molds designed to handle hundreds of thousands of cycles, delivering durability and precision tailored to your specific production goals. High-volume plastic injection molding provides exceptional precision, minimal scrap, and the lowest cost per part in the manufacturing industry for plastic components. For higher production volumes, this is the solution you’ve been looking for.

A key challenge in offshore medical injection molding is ensuring that the resin used for mold testing and production is the correct medical-grade material from an authorized supplier. This is critical for medical devices that require FDA-compliant plastics. At Jade Molds, we source resin exclusively from authorized distributors of Western suppliers in China—never from third-party markets—guaranteeing the quality and compliance your project demands.

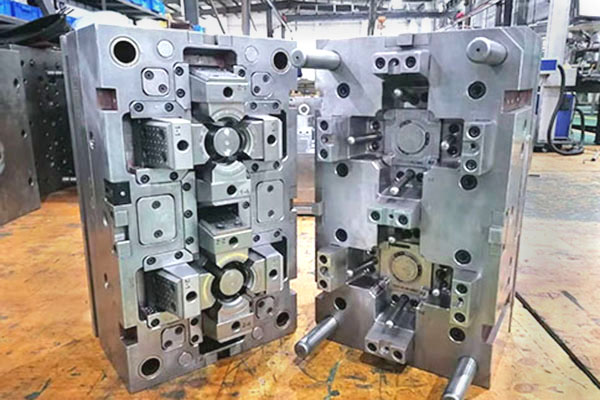

Family injection molding is an excellent option when you have different but similarly sized parts with comparable wall thicknesses. Instead of building five separate molds, you can create one mold for a family of five parts, making it a cost-effective choice for prototype rapid tooling or medium-volume production. Family molds are widely used for various retail and industrial products. When discussing your project, ask your mold maker if a family mold is a suitable solution for your part designs.

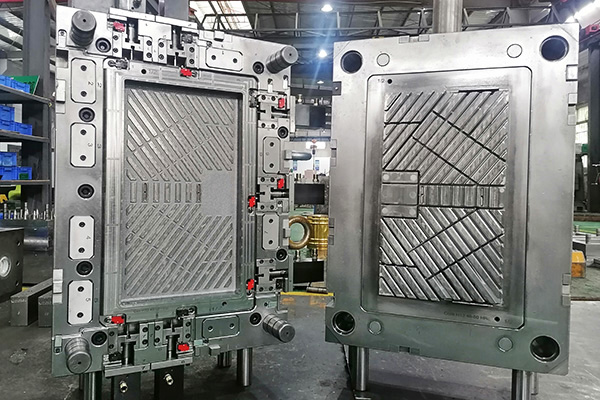

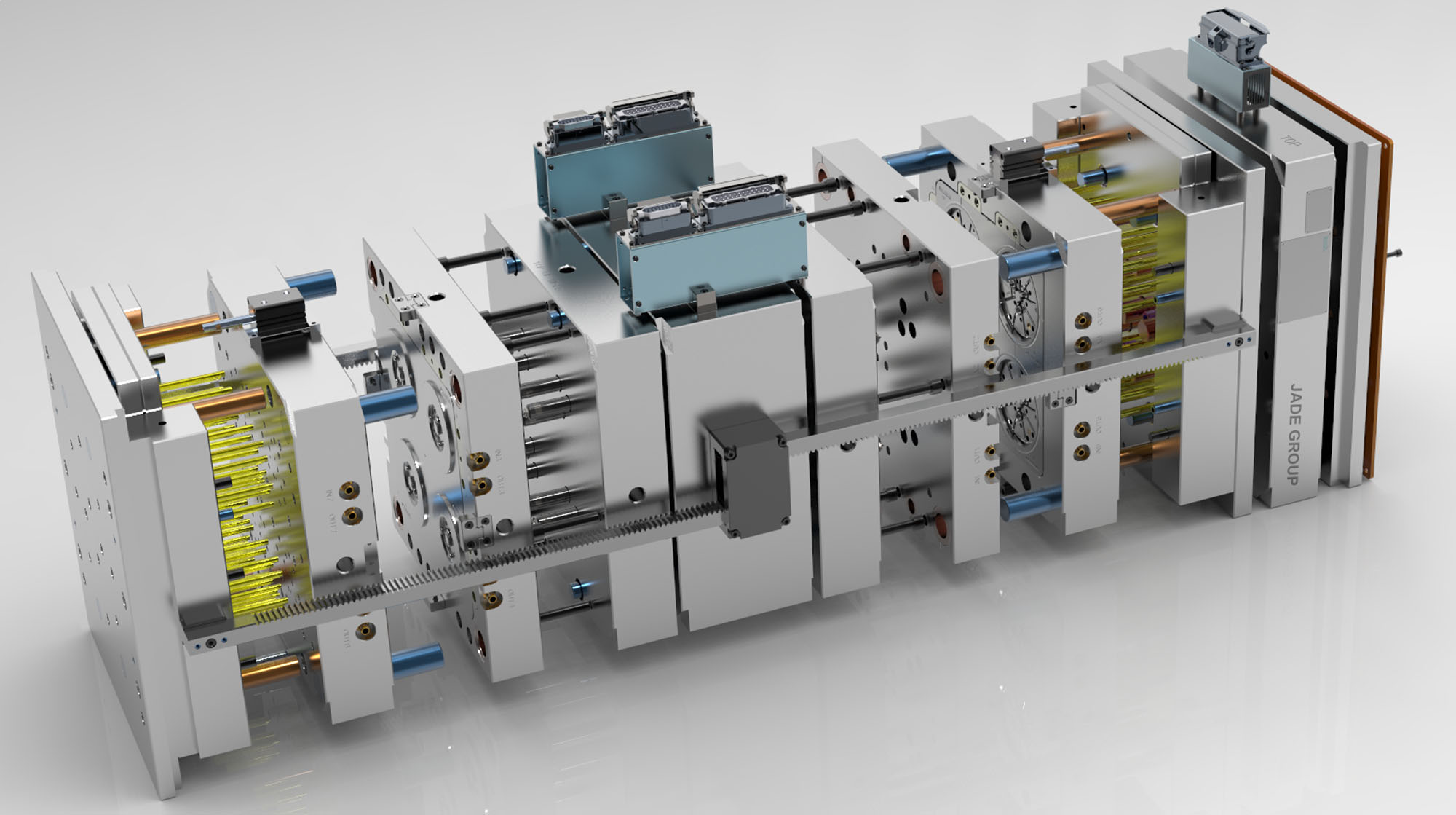

ChatGPT said: ChatGPT Stack molding is an efficient solution for boosting production capacity by using multiple levels of molding faces “stacked” together. At our offshore facilities, we produce 2-, 3-, and 4-level stack molds, supported by our USA-based engineering team to ensure seamless integration with your production setup. However, stack molds aren’t suitable for every project—some injection molders may lack the specialized press capabilities or expertise required. If your part design has a large surface area and you need to increase output, stack molds could be the perfect solution.

When it comes to building injection mold bases, you have three main options: Buy blanks from mold base suppliers and build the mold base in-house—an inefficient and costly approach. Purchase fully machined custom mold bases from domestic suppliers—efficient but expensive. Source fully machined custom mold bases from offshore suppliers—efficient and cost-effective. Why tie up your skilled mold builders with in-house mold base production when you can source high-quality, off-the-shelf options at competitive prices that keep you globally competitive? We're ready to help.

When evaluating a supplier, testing their communication skills is essential—they may not be as reliable as they seem at first. Factory audits are another critical step in supplier qualification, though it can be challenging to discern the truth during these visits. It’s also important to recognize that the injection molding process in China differs significantly from Western practices, a point many overlook. Be cautious of false claims from Chinese suppliers, especially during high tariff periods, and always verify if they use advanced engineering tools like Moldex3D for mold design. Additionally, the factory’s location and the ability to trust a remote supplier—especially in the COVID-19 era—are vital considerations. While a great price is enticing, it’s crucial to properly qualify that price to avoid costly surprises.