With global engineering support and American-led project management.

We specialize in delivering three key injection molding solutions for custom plastic parts:

Export Injection Molds (with Bridge Production)

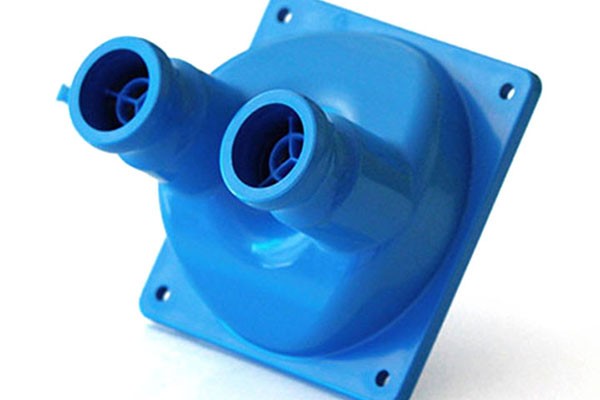

We create custom injection molds and ship them to your facility for in-house part production. If you also require an initial batch of parts with your mold, we provide bridge production to meet your immediate needs.

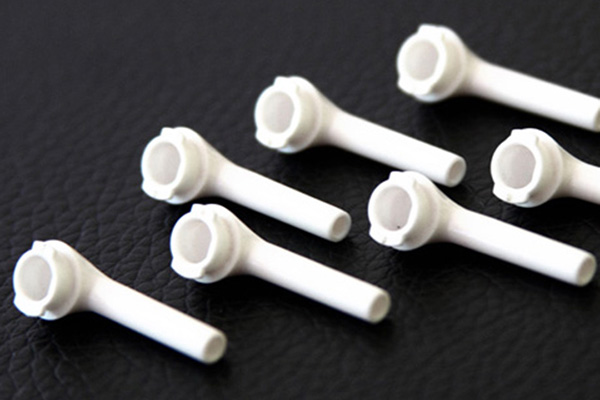

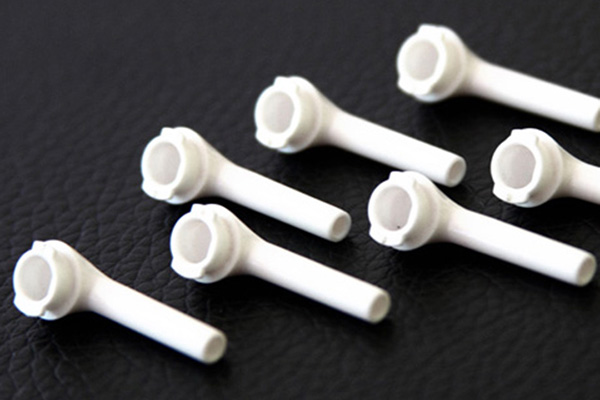

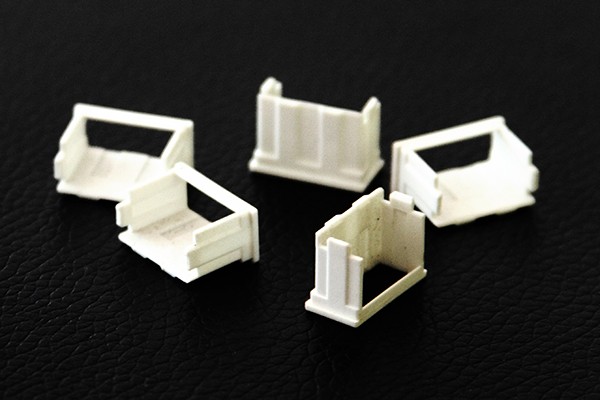

Rapid Tooling (Low-Volume Production)

Designed for speed, we build rapid tools to deliver production-quality parts quickly. We can store your rapid tool at our facility for future orders or ship it to you with the parts. Our P20 rapid tools offer an exceptional ROI, producing significantly more parts compared to typical U.S. or EU rapid tooling programs.

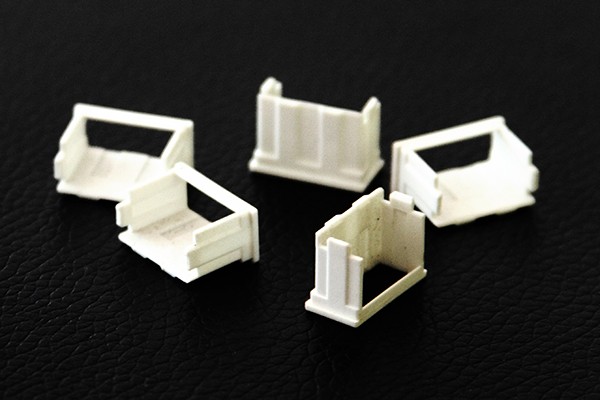

Turnkey Injection Molding (Medium to High-Volume Production)

This full-service solution includes mold creation, part production, and mold storage at our facility. Your mold remains ready for future production runs, providing a seamless, end-to-end injection molding solution.

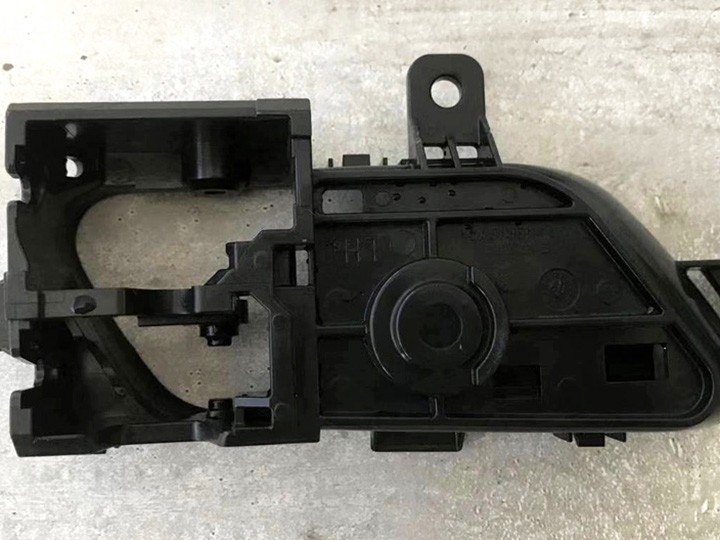

We manufacture parts using various mold types, including two-plate, three-plate, stack, family, overmolds, insert molds, and rapid tooling molds. With 29 in-house presses ranging from 50T to 1100T, we can handle a wide variety of plastic part projects simultaneously.

Injection Mold Making: Export injection molds & in-house mold solutions

Great Plastic Part Price: Globally competitive injection mold & part pricing

Injection Molded Parts: High quality plastic parts (low to high volumes)

Bonus Savings: Uniquely save on mold and part tariffs (USA customers)

Engineering: Global engineering support on your plastic part design

Experience: Injection mold and part production solutions since 2006

Communication: Native English for engineering & project management

Factory: 59,000 sq ft ISO 9001:2015 factory for mold making & parts

Quality: USA quality approach to part quality via our custom QC App

Trust: All paperwork processed through Jade Group INTL, a USA company

Selecting the right material is crucial to the success of your project. Over-engineering with an unnecessarily expensive material can drive up costs, while choosing a cheaper but unsuitable material can compromise part performance and project goals. Our team is here to guide you through the material selection process, ensuring you choose a fit-for-purpose material that balances performance and cost to meet your project’s needs.

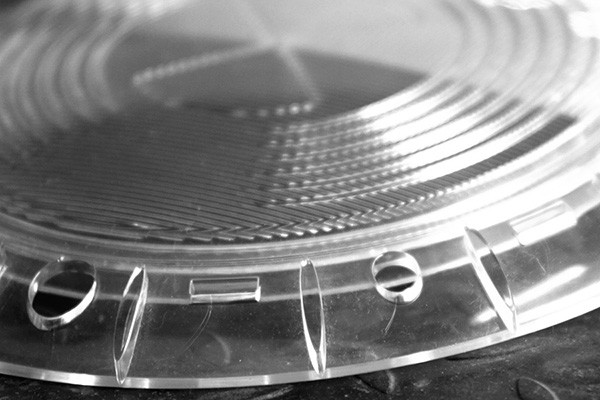

We create molds for export and domestic production across nearly every industry, with the ability to deliver a wide range of surface finishes. From low cosmetic finishes to high mirror polish, bead blasting, etching, or matte finishes, we provide the exact finish your part requires. If your injection-molded part needs secondary processes like pad printing, silk-screening, or assembly, we’ll guide you to the best solution and ensure it’s executed flawlessly.

All rights reserved by:

JADE Group International LLC (JADE Molds)