We’re passionate about Moldex3D, which is why we include it at no extra cost for all injection molding projects—starting right from the RFQ stage.

Our approach is simple: fully leverage Moldex3D to its maximum potential. This powerful tool helps mitigate future risks through highly accurate mold flow simulations and other critical analyses. Time and again, Moldex3D has enabled our engineering teams to identify and address challenging problem areas early in the process, eliminating potential issues before they arise. When paired with the expertise of our experienced engineers, Moldex3D delivers superior molds that go beyond what experience alone can achieve.

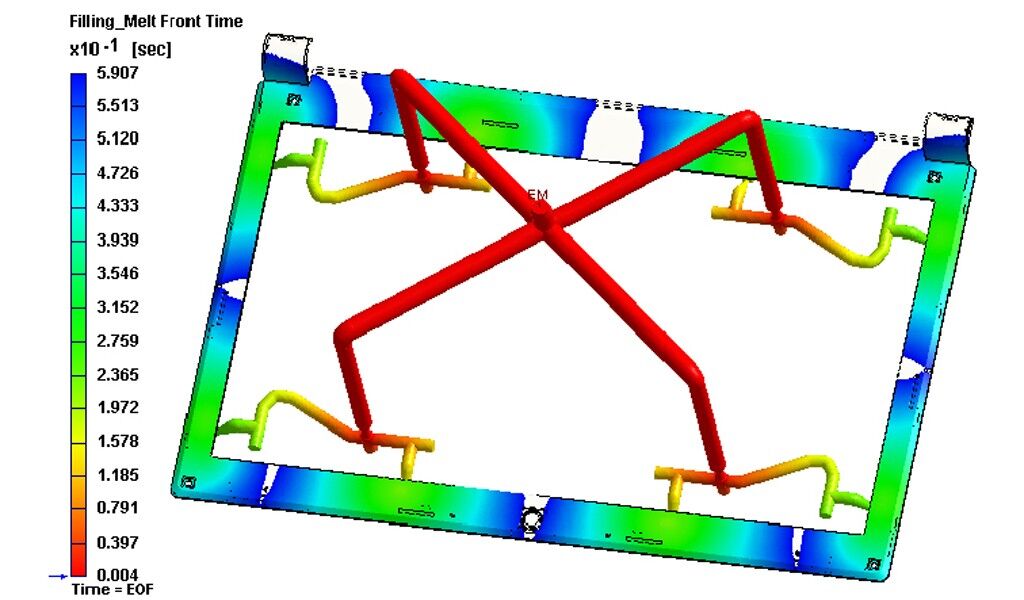

From a macro view to a micro view, Moldex3d mold flow analysis will deliver you injection mold insights such as: Predicting weld lines, 3D fountain flow phenomena, Viscosity heating effects inertia phenomena, Predict injection pressure and evaluate clamping force, Evaluate the runner layout and type, Optimize gate locations and process settings, Simulate the filling process for multi-cavity molds, and much more.

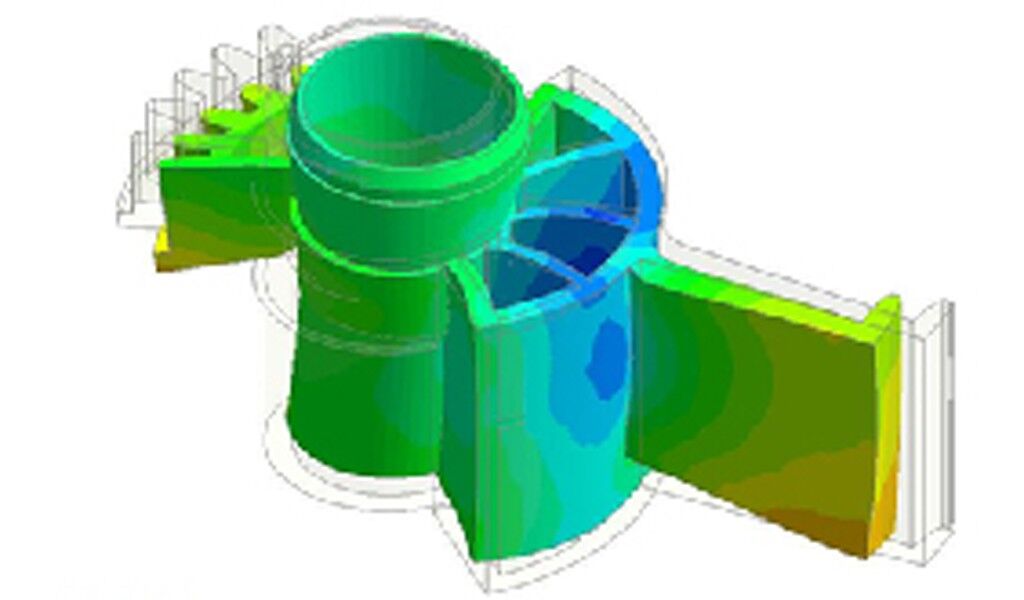

We all know that temperature plays a vital role in producing a successful injection molded part. Moldex3D cooling analysis predicts temperature within a part, runner, cooling channels, etc. and evaluates the efficiency of the cooling system design, which helps to minimize unbalanced cooling issues. Moldex3D will determine the required cooling cycle time and optimize your cooling system to validate the mold cooling system design.

Moldex3D is a powerful tool that analyzes injection mold part designs and simulates mold flow, accurately predicting how parts will form in the mold. It identifies potential problem areas early, allowing you to refine your mold design long before steel cutting begins. However, leveraging this technology to its full potential requires more than just access—it demands the right infrastructure and expertise.

Recognizing its value, Jade quickly invested in the resources and talent needed to maximize Moldex3D’s capabilities. We operate Moldex3D on a 24-CPU global private network, accessible to our USA and Offshore-based Western engineers from anywhere. Our Moldex3D services are led by highly skilled engineering teams with deep mold-building experience, ensuring precise and effective results.

Moldex3D is like running first shots on the screen, providing near-perfect process parameters for an optimized production setup tailored to your needs. Our strategic use of Moldex3D at the start of a project saves significant time later, allowing us to produce more molds with confidence in delivering the desired results on the first or second trial. Time saved means money saved, which is why we include Moldex3D with every mold build—at no extra cost to you.

Once you’ve experienced the precision and efficiency Moldex3D brings to your project, you’ll never look back. It’s a core part of the Jade way of mold building Offshore. Not building a mold with us? No problem. We also offer Moldex3D as a standalone engineering service.

Conduct warp analysis and simulations for thick parts or those with extreme thickness variations. Validate deformation ratios and shrinkage effects while efficiently identifying the root causes of warpage. Evaluate the final part shape before production and assess the impact of unbalanced cooling or in-mold constraints on warpage and more. Moldex3D offers a powerful solution to pinpoint problem areas early, adjust designs, and re-run analyses to confirm the effectiveness of changes.

Moldex3D excels at handling thick parts or those with significant thickness variations. It allows you to evaluate material options, gate designs, and processing conditions with precision. The software predicts gate freeze times, efficient packing times, and optimal packing pressure, ensuring a streamlined process.

Additionally, it provides accurate predictions for clamping force requirements during the packing stage, optimizes packing stage conditions, and forecasts volumetric shrinkage, giving you complete control over your injection molding process.

This feature showcases the invaluable insights you’ll gain from a Jade Moldex3D analysis and simulation report. Each module provides detailed, actionable information, such as identifying likely surface defect locations and offering remedies to address them effectively. The depth of information in a Moldex3D report is truly remarkable and, in our experience, highly accurate when compared to real-world results. Investing a little more upfront to qualify your part and mold design can save you significant time and money later by avoiding costly issues during production.

Moldex3D is a powerful tool for simulating how multiple components interact during the molding process, making it invaluable for insert molds, multi-shot sequential molding, and overmolding. It allows you to visualize plastic flow patterns around inserts, predict temperature variations and heat transfer between the plastic melt and inserts, and detect potential thermal degradation issues. Additionally, its structural analysis capabilities enable accurate predictions of product strength and integrity. By eliminating guesswork, Moldex3D reduces anxiety in the mold-building process and ensures better outcomes.